Discovering the Benefits of Fillet Welding in Fabrication: Cost-effective Solutions for Diverse Industries

In the realm of fabrication, the utilization of fillet welding provides an engaging proposal for sectors seeking economical options without compromising structural honesty. The advantages of fillet welding expand beyond simple monetary savings to encompass improved structural effectiveness, adaptability throughout diverse commercial applications, and the guarantee of superior toughness and longevity. As we navigate through the practical advantages that fillet welding offers, a much deeper understanding arises of exactly how this welding technique can change construction processes across different industries.

Cost-efficient Option for Construction

Fillet welding functions as an economical solution in fabrication processes, giving both effectiveness and resilience. This welding strategy includes signing up with two pieces of metal at an angle, forming a triangular cross-section. The simpleness of fillet welding makes it a popular choice in various markets, consisting of building, automotive, and production.

One of the key benefits of fillet welding is its ability to decrease product and labor prices. By utilizing fillet welds as opposed to other complicated joint designs, producers can conserve cash on materials and manufacturing time. In addition, fillet welding needs marginal preparation compared to various other welding strategies, even more reducing manufacture costs.

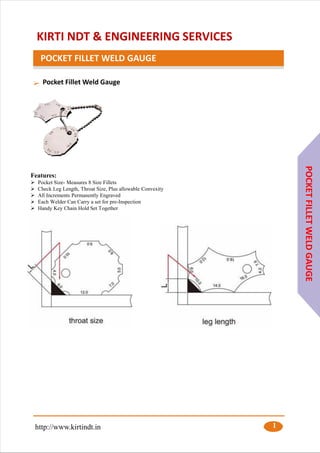

Additionally, fillet welds supply excellent structural toughness, ensuring the durability and sturdiness of the made components. The triangular shape of the weld disperses stress and anxiety more evenly, reducing the likelihood of joint failing (Gauge Fillet Weld). This architectural honesty not just improves the general quality of the completed product yet likewise lowers maintenance and repair work costs in the long run

Boosted Structural Performance With Fillet Welding

Enhancing architectural effectiveness via the application of fillet welding strategies is an essential element of ensuring optimum efficiency and resilience in produced structures. Fillet welding plays a vital function in improving architectural effectiveness by successfully dispersing tons and stress and anxieties throughout the bonded joints. By creating a smooth change between the linked parts, fillet welds aid to enhance the general toughness and security of the structure.

Among the significant benefits of fillet welding in enhancing architectural effectiveness is its capacity to join products of varying densities. This flexibility enables for the building of lightweight frameworks without jeopardizing on toughness. Furthermore, the smooth account of fillet welds decreases stress and anxiety concentrations, which can aid stop premature failing of the welded joints.

Furthermore, fillet welding makes it possible for the manufacture of complicated geometries easily, giving designers with even more flexibility in creating reliable and ingenious structures. By optimizing the style and positioning of fillet welds, designers can make best use of the architectural efficiency of produced elements, inevitably leading to set you back savings and improved performance in varied industries.

Adaptability in Diverse Industry Applications

With its capacity to provide to a variety of product densities and geometric complexities, fillet welding stands as a why not check here versatile construction method that locates applications throughout varied sectors. One key area where fillet welding succeeds is in the production field, where it is used in the manufacturing of hefty machinery, devices, and architectural parts. The vehicle industry also takes advantage of fillet welding, using it in the setting up of lorry structures, framework, and various other critical structures. In the construction field, fillet welding plays an important role in signing up with steel light beams, columns, and various other architectural components. Furthermore, the aerospace market counts on fillet welding for the construction of aircraft components, guaranteeing strength and sturdiness in essential components. Moreover, the oil and gas industry utilizes fillet welding in the construction of pipes, systems, and storage containers, where the durable welds give honesty and longevity to these structures. Overall, the versatility of fillet welding makes it an essential procedure in different industries, providing cost-effective remedies for complicated manufacture requirements.

Superior Strength and Durability

Fillet welding plays a vital duty in accomplishing these features due to its capacity to provide substantial stamina by dispersing loads equally throughout the bonded joint. As an outcome, frameworks fabricated using fillet welds check my reference show raised durability and can stand up to considerable mechanical forces without endangering their integrity.

The remarkable stamina and toughness used by fillet welding make it a perfect choice for applications in industries such as construction, auto, aerospace, and production, where architectural honesty is extremely important. By utilizing fillet welds in fabrication, makers and engineers can guarantee that their items fulfill rigorous high quality and safety and security requirements while optimizing cost-effectiveness and manufacturing efficiency. Essentially, the outstanding durability and longevity given by fillet welding make it a favored welding method for creating durable and robust frameworks throughout diverse markets.

Practical Advantages of Fillet Welding

Offered the shown exceptional toughness and sturdiness in bonded joints, the sensible benefits of fillet welding prolong beyond architectural integrity to encompass performance and cost-effectiveness in fabrication processes. In addition, fillet welding enables for increased efficiency due to its convenience in joining various types of products, forms, and densities. Generally, the functional benefits of fillet welding make it a useful choice for business seeking economical and efficient solutions in fabrication.

Conclusion

Finally, fillet welding provides a cost-efficient remedy for manufacture, giving enhanced architectural performance, convenience in varied sector applications, remarkable toughness, and durability. The functional advantages of fillet welding make it a recommended selection for numerous construction projects across various industries. Its ability to successfully sign up with products while maintaining structural integrity makes it a beneficial technique for guaranteeing reputable and top quality results in welding applications.

Additionally, fillet welding needs very little preparation compared to other welding methods, additionally reducing construction expenses.

Provided the demonstrated remarkable toughness and sturdiness in bonded joints, the useful advantages of fillet welding expand beyond architectural honesty to include performance and cost-effectiveness in fabrication processes - Gauge Fillet Weld.In final thought, fillet welding supplies an economical remedy for fabrication, providing boosted architectural efficiency, adaptability in varied sector applications, exceptional stamina, and sturdiness